Background technique:

The forming process of automobile aluminum alloy wheel hub mainly includes: gravity casting, low pressure casting and forging process. The casting process is divided into two types: gravity casting and low pressure casting. At present, low pressure casting and metallic gravity casting are widely used at home and abroad.

However, the wheels using the casting process are heavier in weight, low in strength, and poor in mechanical properties. The aluminum alloy wheels produced by forging technology have the highest cost, the technology is complicated, and the forging process is extremely costly. It can only be used in the high-end market. Impossible to popularize.

Technical realization elements:

The purpose of the present invention is to provide a spinning process for high-strength and lightweight aluminum alloy wheels. On the basis of casting, the rim is rotated and stamped to change the internal structure of the metal at the rim, and the molecules are arranged in a fibrous shape with higher density. , Compared with ordinary casting, it has higher mechanical performance, which is higher strength and higher toughness.

The purpose of the present invention is achieved as follows: a high-strength lightweight aluminum alloy wheel spinning process,

Including the following steps:

① The spinning billet with spokes made by gravity casting is first subjected to X-ray inspection, and the qualified spinning billet is sent to the heating room for heating;

②The heated spinning blank is placed on the rotating clamp and the inner spinning film driven by the spindle of the spinning machine through a mechanical arm;

③The spinning machine drives the spinning billet to rotate at a high speed, and a fire spray device is set near the outer surface of the spinning billet to heat and keep the outer surface of the spinning billet;

④Set the radial and axial process parameters of the hydraulically driven spinning roller, the spinning roller applies pressure to the initial spinning position on the outer surface of the spinning blank rim; the spinning roller is distributed at least two circumferentially on the outer circumference of the spinning blank First, the first spinning roller is spinning according to the process parameters, and the rim part is compressed and stretched according to the set path; after the first spinning roller travels the set distance along the path, the second spinning roller presses the rim again. The spinning part moves synchronously behind the first spinning roller and compresses and stretches the rim again; if there are more than three spinning rollers, they follow the last spinning roller in turn, and gradually move through the spinning rollers. Reduce the thickness of the rim of the spinning blank;

⑤After the first spinning roller completes one stroke, it leaves the surface of the spinning blank rim and returns to the initial position for secondary spinning or preparation for processing the next spinning blank; the second spinning roller and subsequent spinning The pressing roller repeats the action of the first spinning roller until the rim is formed;

⑥Use a mechanical arm to remove the formed wheel hub from the spinning machine, and perform cooling treatment and rim thickness inspection;

⑦ Finish machining or/and painting on qualified wheels.

Preferably, the spinning roller forms an acute angle with the surface of the rim.

Preferably, the acute angle of inclination is 20°-30°.

Preferably, the thickness of the rim compressed by the spinning roller each time is ≤10mm.

Preferably, the heating temperature of the spinning billet in the heating room is 300°C-350°C.

Preferably, the raw material of the spinning billet is ZL101A aluminum alloy or A356.2 aluminum alloy.

Preferably, there are more than two sets of the fire spray device arranged on one or both sides of the hub according to the axial direction of the hub.

Compared with the prior art, the present invention has the following outstanding and beneficial technical effects:

1. The thinnest rim thickness, the lightest weight, and the lowest fuel consumption;

2. The tensile strength and elongation of the rim are increased by more than 10%;

3. The X-ray flaw detection level of shrinkage and porosity of the rim reaches the level 1 standard;

4. The deflation rate is within 0.3%, which is much higher than the industry standard;

5. Set up a fire spray device near the outer surface of the spinning blank to keep the workpiece in a high-temperature hot spinning state, with low spinning resistance and easier shaping of the rim; and install two or more sets of fire spray devices in the axial direction to cope with the heating of the rim extension Insulation

6. There are multiple spinning rollers, which reduces the number of reciprocation of the spinning roller, improves production efficiency, and reduces the fire heat preservation time of the fire spray device;

7. The spinning roller forms an acute angle with the rim surface. The pressure of the spinning roller is divided into horizontal component force and vertical component force of the rim surface. The horizontal component force pushes the rim to extend, and the vertical component force makes the rim more compact and has high structural strength.

detailed description

The present invention will be further described below with specific embodiments in conjunction with the drawings.

A spinning process for high-strength and lightweight aluminum alloy wheels includes the following steps:

① The spinning billet with spokes made by gravity casting is first subjected to X-ray inspection, and the qualified spinning billet is sent to the heating room for heating;

②The heated spinning blank is placed on the rotating clamp and the inner spinning film driven by the spindle of the spinning machine through a mechanical arm;

③The spinning machine drives the spinning billet to rotate at a high speed, and a fire spray device 5 (such as a gas torch) is installed near the outer surface of the spinning billet to heat and keep the outer surface of the spinning billet;

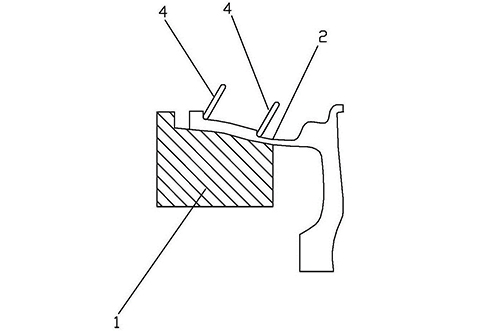

④Set the radial and axial process parameters of the hydraulically driven spinning roller 4. The spinning roller 4 applies pressure to the initial spinning position on the outer surface of the spinning blank rim; as shown in Figure 3, the spinning roller 4 is spinning There are two at least circumferentially distributed on the outer periphery of the green compact. The first spinning roller 4 is firstly spun according to the process parameters, and the rim part is compressed and stretched according to the set path; after the first spinning roller 4 travels along the path for a set distance, The second spinning roller 4 then presses the initial spinning position of the rim, and then moves synchronously behind the first spinning roller 4 to compress and stretch the rim again; if there are more than three spinning rollers 4, follow the previous one in turn The spinning roller 4 moves behind, and the thickness of the rim of the spinning blank is gradually reduced through the spinning of the spinning roller 4;

⑤ After the first spinning roller 4 completes a stroke, it leaves the surface of the spinning blank rim and returns to the initial position for secondary spinning or preparing for processing the next spinning blank; the second spinning roller 4 and after The spinning roller 4 repeats the action of the first spinning roller 4 until the rim is formed;

⑥Use a mechanical arm to remove the formed wheel hub from the spinning machine, and perform cooling treatment and rim thickness inspection;

⑦ Finish machining or/and painting on qualified wheels.

As shown in Fig. 2, the spinning roller 4 forms an acute angle of inclination with the surface of the rim, and the acute angle of inclination is 20°-30°.

Among them, the thickness of the rim compressed by the spinning roller 4 each time is ≤10mm.

Among them, the heat treatment temperature of the spinning blank before spinning is 300°C-350°C.

Among them, the raw material of the spinning billet is ZL101A aluminum alloy or A356.2 aluminum alloy.

The foregoing embodiments are only preferred embodiments of the present invention, and do not limit the scope of protection of the present invention accordingly. Therefore: all equivalent changes made in accordance with the structure, shape, and principle of the present invention should be covered by the protection of the present invention. Within range.

Technical characteristics:

1. A spinning process for high-strength and lightweight aluminum alloy wheels, including the following steps:

① The spinning billet with spokes made by gravity casting is first subjected to X-ray inspection, and the qualified spinning billet is sent to the heating room for heating;

②The heated spinning blank is placed on the rotating clamp and the inner spinning film driven by the spindle of the spinning machine through a mechanical arm;

③The spinning machine drives the spinning billet to rotate at a high speed, and a fire spray device is set near the outer surface of the spinning billet to heat and keep the outer surface of the spinning billet;

④Set the radial and axial process parameters of the hydraulically driven spinning roller, the spinning roller applies pressure to the initial spinning position on the outer surface of the spinning blank rim; the spinning roller is distributed at least two circumferentially on the outer circumference of the spinning blank First, the first spinning roller is spinning according to the process parameters, and the rim part is compressed and stretched according to the set path; after the first spinning roller travels the set distance along the path, the second spinning roller presses the rim again. The spinning part moves synchronously behind the first spinning roller and compresses and stretches the rim again; if there are more than three spinning rollers, they follow the last spinning roller in turn, and gradually move through the spinning rollers. Reduce the thickness of the rim of the spinning blank;

⑤After the first spinning roller completes one stroke, it leaves the surface of the spinning blank rim and returns to the initial position for secondary spinning or preparation for processing the next spinning blank; the second spinning roller and subsequent spinning The pressing roller repeats the action of the first spinning roller until the rim is formed;

⑥Use a mechanical arm to remove the formed wheel hub from the spinning machine, and perform cooling treatment and rim thickness inspection;

⑦ Finish machining or/and painting on qualified wheels.

2. The spinning process of a high-strength lightweight aluminum alloy wheel hub according to claim 1, wherein the spinning roller forms an acute angle with the surface of the rim.

3. The spinning process of a high-strength lightweight aluminum alloy wheel hub according to claim 2, wherein the acute angle of inclination is 20°-30°.

4. The spinning process of a high-strength and lightweight aluminum alloy wheel hub according to claim 1, characterized in that the thickness of the rim compressed by the spinning roller each time is ≤10mm.

5. The spinning process for high-strength and lightweight aluminum alloy wheels according to claim 1, wherein the heating temperature of the spinning billet in the heating room is 300°C-350°C.

6. The spinning process for high-strength and lightweight aluminum alloy wheels according to claim 1, wherein the raw material of the spinning billet is ZL101A aluminum alloy or A356.2 aluminum alloy.

7. The spinning process of high-strength and lightweight aluminum alloy wheel hub according to claim 1, characterized in that: the fire spraying device is arranged in more than two sets on one or both sides of the hub according to the axial direction of the hub.

Technical summary

The invention provides a spinning process for a high-strength and lightweight aluminum alloy wheel hub. The rim is rotated and stamped on the basis of casting, which changes the internal structure of the metal at the rim, and the molecules are arranged in a fibrous shape with higher density. Compared with ordinary casting, it has higher mechanical performance, manifested by higher strength and higher toughness; the thinnest rim thickness, lightest weight, and lowest fuel consumption; rim tensile strength and elongation increased by more than 10%; rim shrinkage cavity shrinkage The X-ray flaw detection level reaches the level 1 standard; the flatness rate is within 0.3%, which is much higher than the industry standard.

We are engaged in the production and independent import and export of aluminum alloy wheel in china, with more than 2,0000 models of aluminum alloy wheels, about 100,000 inventories, and fast delivery. We provide custom wheels and generation production services, you can provide us with a wheel style map, our designers will design you a beautiful and high quality wheel, welcome to contact us!

If you don't find the wheel style you need, you can send an email to jihoowheels@jihoosh.com and we will send you the wheel style you need according to your description!We will provide you with quality China wheel and excellent service.